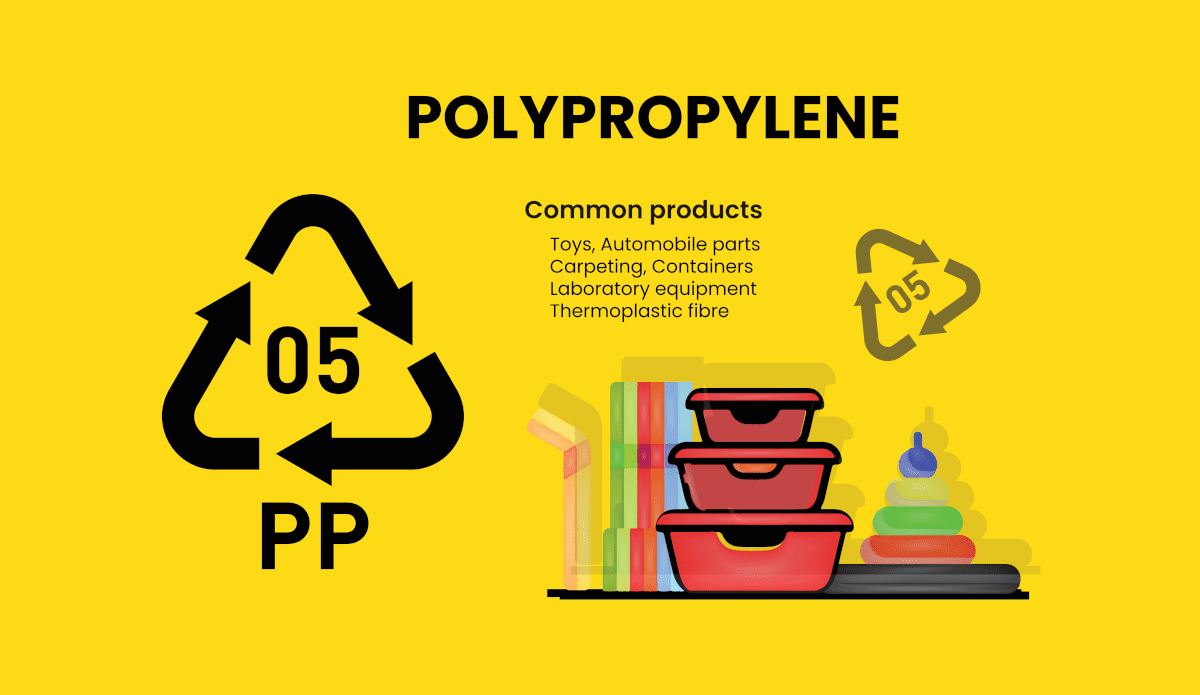

PP (5) is a type of plastic called polypropylene. Because it’s light, flexible, and durable, it is turned into a huge variety of different products that you use every day.

PP stands for polypropylene, and the (5) denotes the recycling category. PP (5) has a number of properties that make it excellent for many different applications. It’s the second-most produced plastic type in the world, with about 45 million tonnes created each year. About 30% of that is used as packaging. Electrical and equipment manufacturing use 13% each, while household appliances and the automotive industry use about 10%.

It’s popular because it’s so versatile, with a number of advantages over other plastic types.

- Strong: PP is highly flexible and has elastic properties, retaining its shape even after bending. It has a tensile strength of around 4,800 psi, and a surface hardness of 92 on the Rockwell R scale, so it’s quite soft, allowing for bending and flexing.

- Lightweight: PP5 is low in density comparted to other common plastics, making it lighter to ship.

- Stable: PP is resistant to fats, acids, alkaline, and other chemicals such as chloride, acetone, boric acid, nickel sulfamate, and hydrochloric acid. However, it is susceptible to oxidisation and at higher temperatures may not be appropriate for chemicals.

- Low friction: The surface is ‘slippery’ and frictionless

- Insulation: Highly resistant to electricity

- Non-permeable: PP5 does not absorb water. In a 24 hour soaking test, polypropylene absorbs less than 0.01% of its weight.

- Thermoplastic: PP melts at 163.8oC and can be cooled and heated again as needed. This means it can be injection moulded and also recycled many times

- Easily welded: Because of its low melting point, polypropylene can be easily welded if a join is required

- 3D Printing: Although PP is challenging to print with in 3D, it is ideal for prototyping and has a lot of advantages over more brittle/ firm plastic types.

What is PP (5) Used For?

Because it has so many good qualities, it’s ideal for a huge range of uses.

Cosmetic Packaging

Because polypropylene is resistant to chemicals, this makes it ideal as packaging for cosmetics. Due to its flexibility, PP also is used to create ‘living hinges’, which are the hinges on top of flip-top lids for container like shampoo and conditioner bottles.

Food and Drinks

In its virgin form (not recycled), PP5 is considered an excellent material for food and drink packaging. That includes things like yoghurt container, straws, bottle caps, as well as other packaging types. Tomato sauce bottles, with their living hinges, are a great example of PP (5) use.

It’s resistant to heat beyond most kitchen temperatures, making it safe for use in heating/ storage of food. This is why our range of food pails are in polypropylene; from 1.1L to 20L, plain, coloured, or in-mould-labelled, our extensive range will suit a huge variety of food producers.

Automotive Applications

Because it’s easily weldable, low cost, and with low friction, PP has excellent mechanical properties. It’s used in applications such as battery trays and cases, bumpers, interior trims, and instrument panels and dashboards.

Fabrics and Fibres

Due to its high levels of flexibility, PP5 is used in strapping, staple fibres, filament, and tape. It’s highly flexible and yet strong, ideal for many types of packaging and wrapping materials.

Industrial Uses

Its strength and resistance to chemicals means that PP5 is used in many industrial ways. Jerry cans, chemical tanks, and piping are all ideal uses. It’s also used to protect parts in machinery, to prevent delicate components from scratches or breaking upon impact.

Consumer Goods

Furniture, appliances, luggage, toys, and houseware all use PP5 plastic. Most plastic chairs and outdoor furniture are made from PP.

Disadvantages of PP5

Polypropylene has three main disadvantages.

- UV Sensitive: Compared to other plastics, PP5 has poor resistance to UV light

- Poor Adhesion: PP5 has poor adhesion properties, so paint or glues do not stick well, however it does weld easily

- Temperature: While it is stable at ambient temperatures, it is not recommended for high temperature use, and can become brittle at low temperatures.

Recycling PP 5

Polypropylene, on the first instance, is used primarily for food items. Once it’s recycled, it’s no longer considered ‘virgin’ (food grade), but it is recyclable and has a number of uses. Rope, carpet, clothing, speed humps, garden tools, compost bins, and a range of other items can be created from recycled PP.

Because it can be melted down so easily, it can be recycled up to six times. Added to this is that generally all the components of an item of packaging, including the labels and lids, are PP, making it easy to recycle.

Currently only about 1% of PP plastic is recycled, but in New Zealand PP plastic is wanted in recycling. This is because it’s cheaper to re-use it than ship it in brand-new from overseas. Most curb side recycling pick-ups accept number 5 plastics.

Need PP (5) Plastic Packaging?

At IFP Group, we have a full range of polypropylene products. Contact us to find out if we have what you want, with our in-mould labelling and custom manufacturing options.